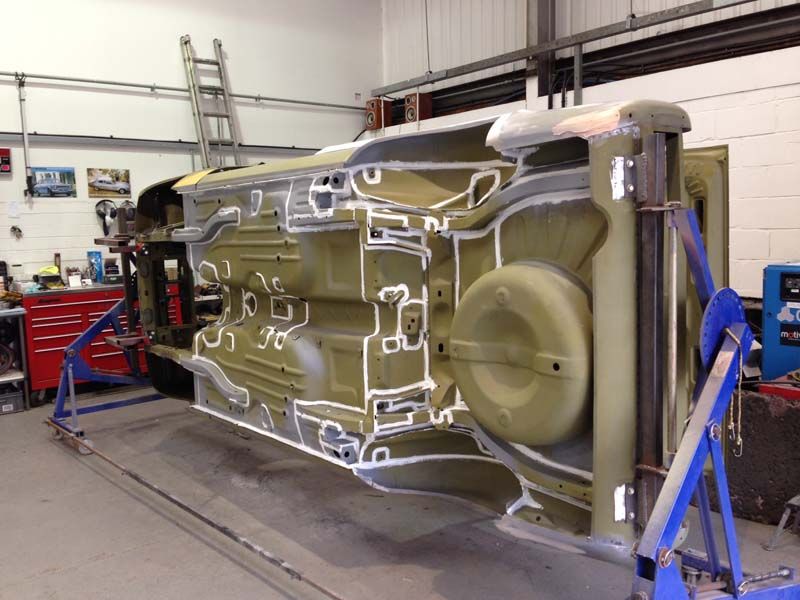

now at the soda blasters, here is the sight that greeted when I arrived:

turning the car over...

Looking preety good at this point. A few areas to be repaired, but no huge suprises here!

Overall, very please with the process and the condition of the car. This should dispel any doubts about soda blasting removing sealer and underseal. This car was covered in at underneath, but you would never know it looking at these pictures.

Here's a video of the process.

The first stage is just fine soda, almost like talcum poder. This takes the paint off, but not the rust. You can see how it leaves the panel, compared with the area underneath that as also be blasted with a more aggressive media to key the surface and clean way any rust. Notice how the angle of the nozel is kept mostly at a very low angle to the body work. Even with this process, you can damage panels if you are careless, but with sand blasting, due to it being far more aggressive, panel damage can occur due to careless use and pure heat build up in a panel. Touching this panel the second the soda was turned off revealed a cold panel, no heat build up whatsoever.

Here you can see rust around the holes for the fake vents. This will be cleaned off with a more aggressive media:

Here is the general view of restore a ford. they have since moved.

Lots going on, with 2 RS3100's nearly completed, an escort mexico, 2 mk3 capris and a Mk 1 GXL capri. Elsewhere there is another RS3100 awaiting attention and a mk 1 granada estate awaiting an epic rebuild. Stuart also has three other personal projects that he never really gets time to work on.

another view. To the right is the spray booth.

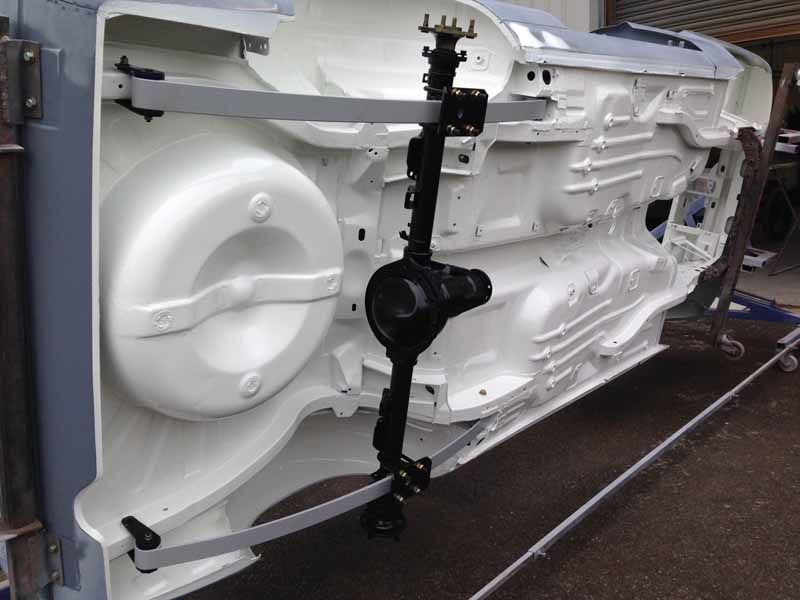

so here is my car, all etch primed up and looking pretty good..

There are lots of small areas that have come to light, as well as damage. You can see some perforation where the screen pillar meets the scuttle, so this will be opened up for investigation. You can also see a dent on the screen pillar.

Here you can see some leaded repairs to the wheel arch, so not as clean as the other side, still excellent considering the cars age!

Not really visible is that the seam where the rear quarter joins the wing is holed, so where the panel forms a flange that fold horizontally to meet the top of the sill, there is some corrosion to the extent that the flange doesn't really exist, so this flange will be remade when the new sills go on.

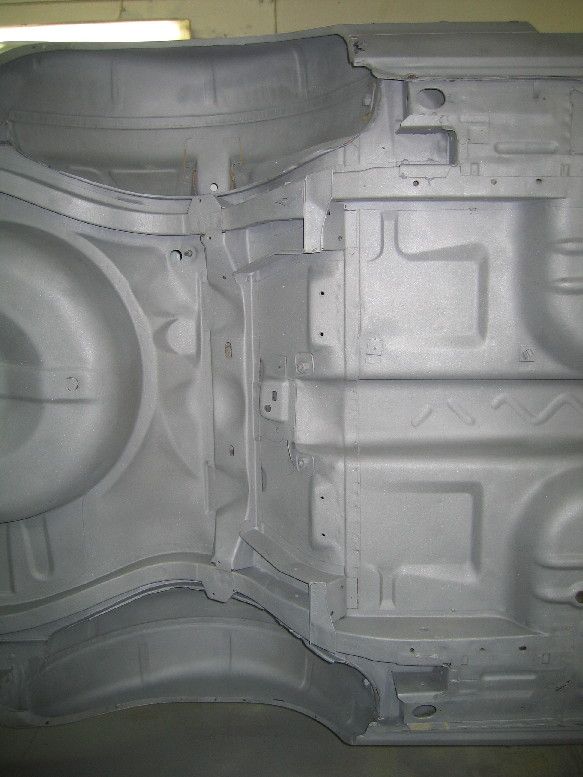

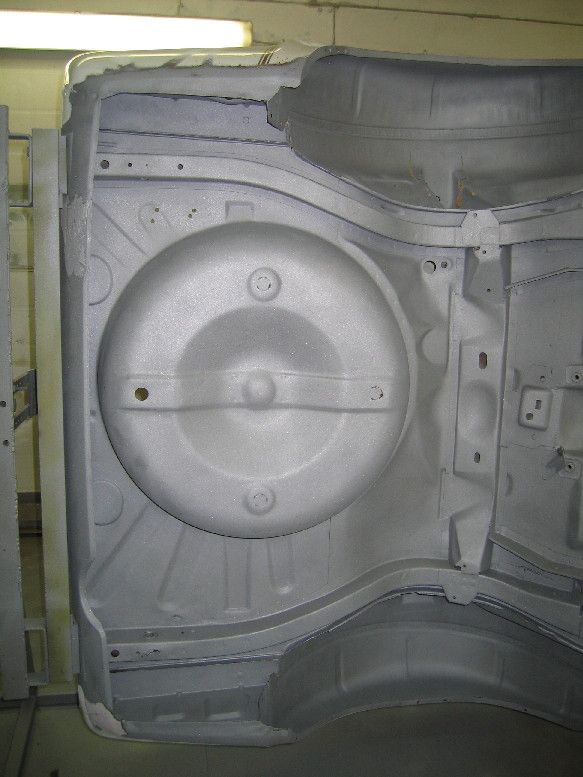

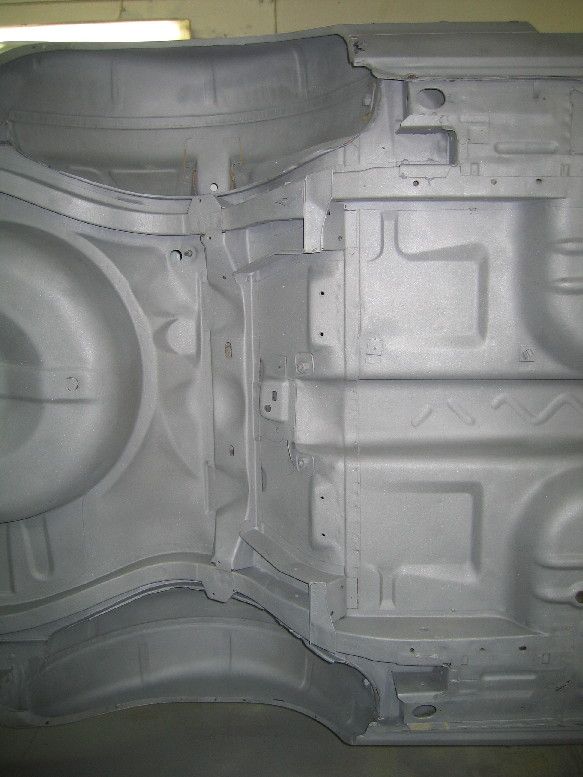

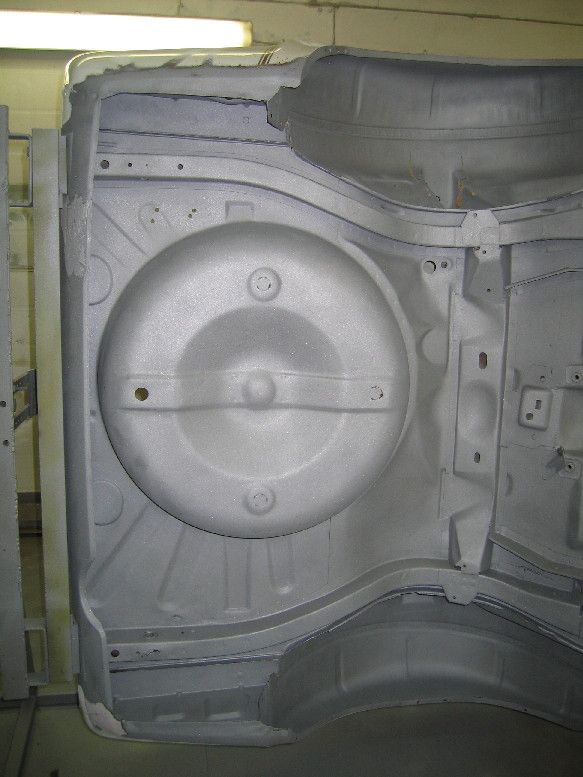

The inside has been blasted and primed as well. some light coming in at the passenger side at the end of the sill. The sills will actually be replaced, inner and outer, as they are ok, but the flanges where they meet are swelling, so as I'm not planning on doing this again, the sills are coming off.

More smaller areas to be done, but to be expected..

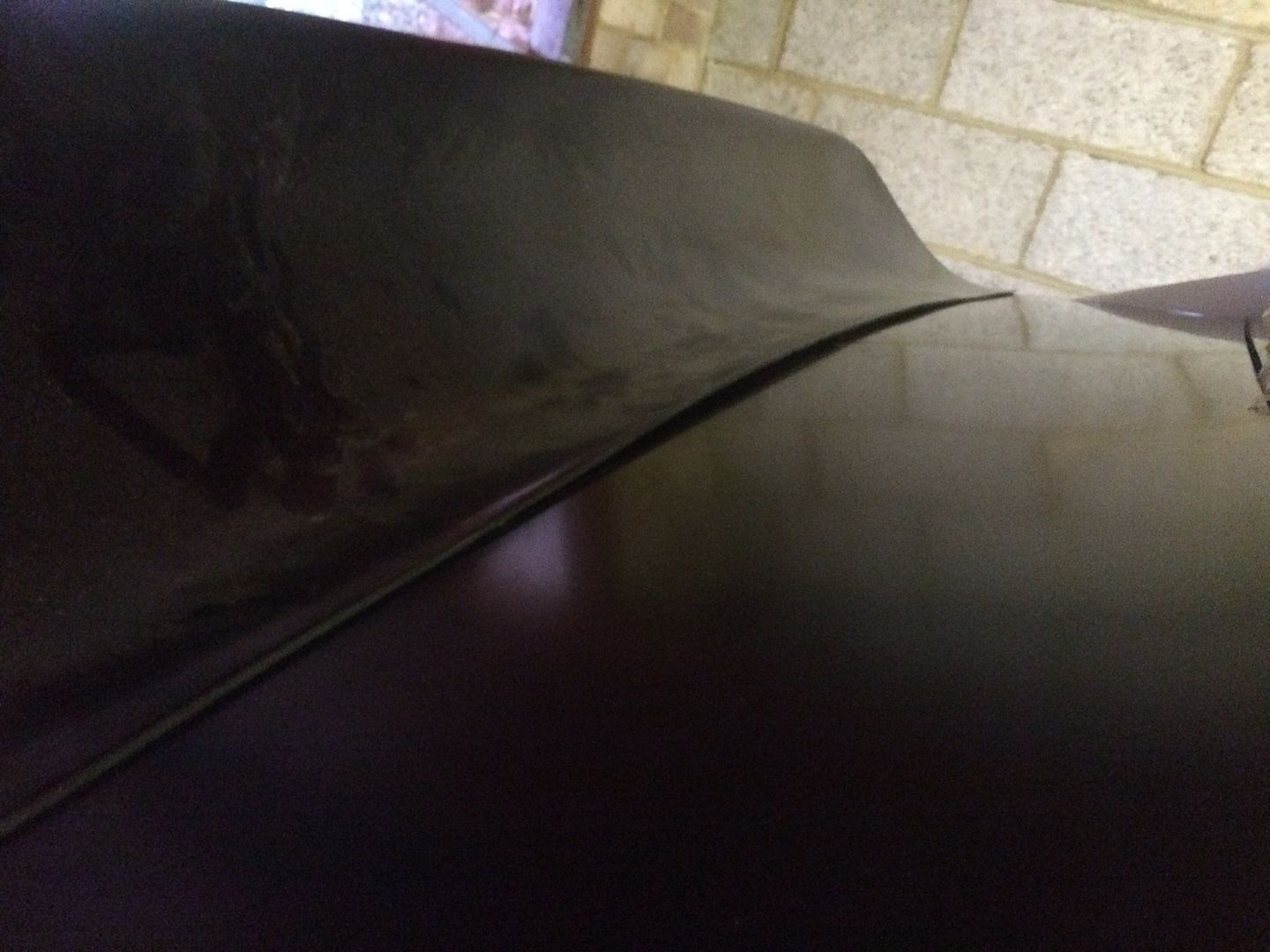

I was concerned about how the roof had been fitted, but other than just being tacked here...not a big issue to correct, really happy with these

It's difficult to see but there are some sizable dents in the bonnet on the passenger side. I could start looking for a new bonnet, but being such a big panel, these are easily damaged. I've bought two bonnets for my mk 2 capri, only to find they have lots of ripples in them due to bad storage, so I'll keep an eye out for another bonnet. I could find a second hand one that once blasted, could be worse than mine, while my one has the merits of otherwise being fine and rot free, so pending another excellent bonnet coming up, then plan is to repair this one.

Finally, and difficult to photograph, both rear quarters have very subtle dents below and to the rear of the rear quarter windows, so these will be looking at. My fear of having to replace rear quarters has been placated, as otherwise, these are very good. With rear quarters fetching up to 2k a side, this would put a serious dent in my budget if these were needed.

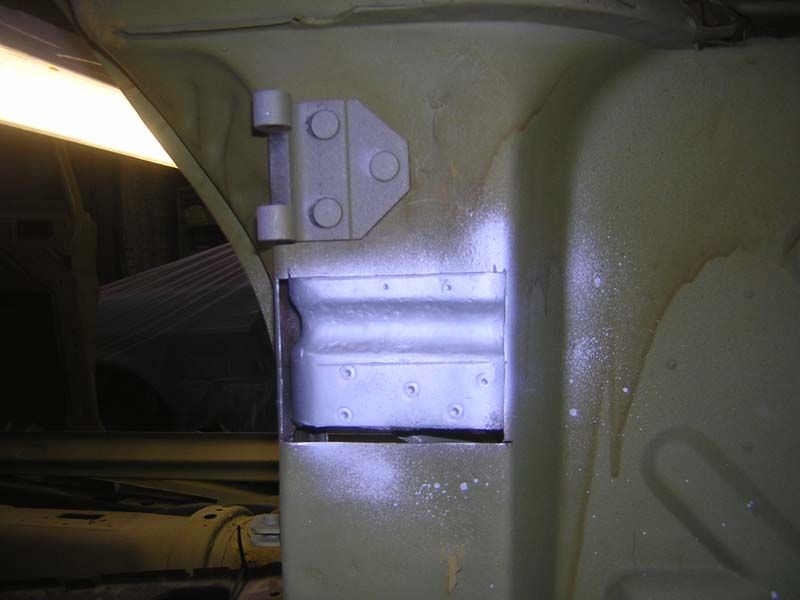

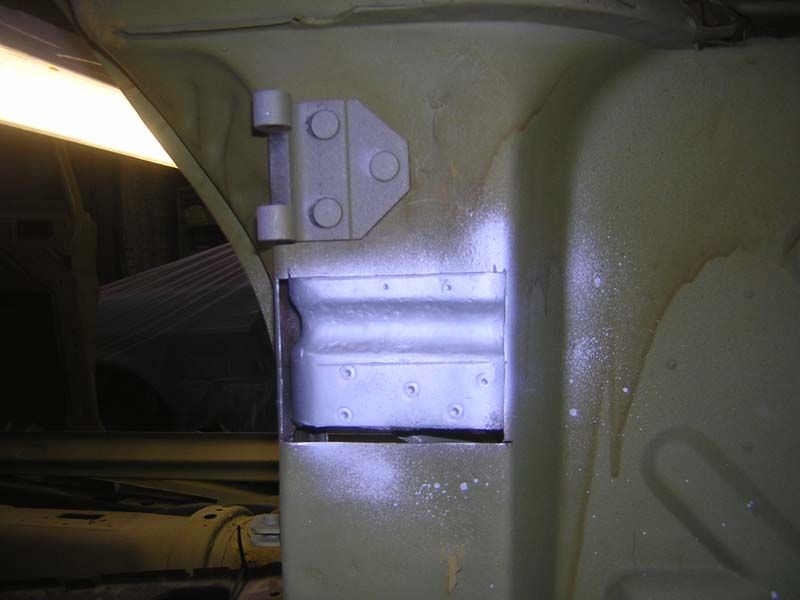

Drivres side sill and bottom of the A post. the decision was made to replace this bottom section and the whole inner sills. I've used original Ford outer sills, express steel panels inners, which really are an excellent fit.

Here the inner sill is off and the scuttle to A post flange has been rebuilt, ready for the new A post lower section

while here's the area where the scuttle and floor overlap, so this needs cutting out and remaking..

all done. Should look pretty original here, as Stuart has recreated the overlapping edges as per the original panels.

another multi layered area, the seat mount..

spt welds drilled out to release the reinforcing plate below.

and the rusty metal cut out

New plate welded in and reinforcing plate underneath re-spot welded into place

Another area at the back, just forward of the front rear spring mount. Another double layered area. This one has a large patch over it in the original photos.

so once again, cut out the rot.

and replace with new.

New inner sill in place

but the base of the outer wheel housing needs attention as well.

so this is dealt with before the new outer sill can go on

new inner sill from inside the car

New outer sill in place along with the A post repair panel, sourced from express steel panels. All the welds are but welds, so they can be ground down and new and old metal blended into one..

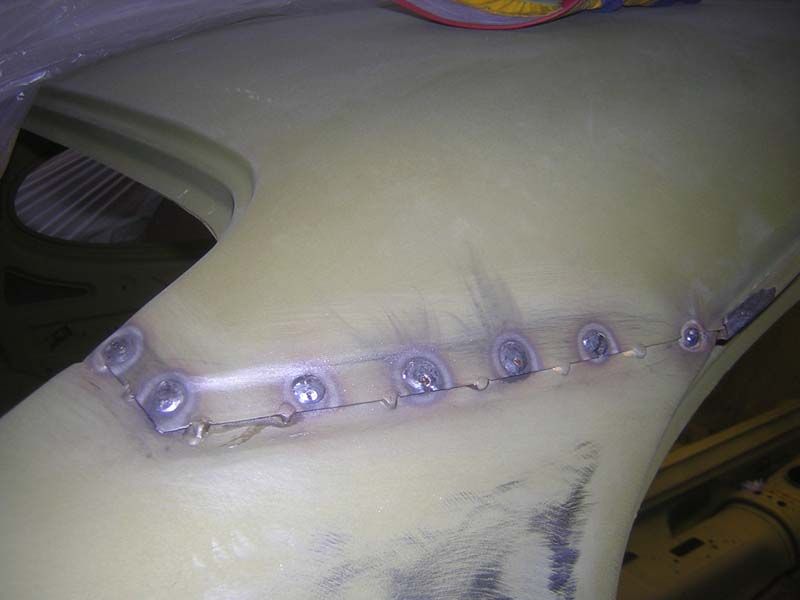

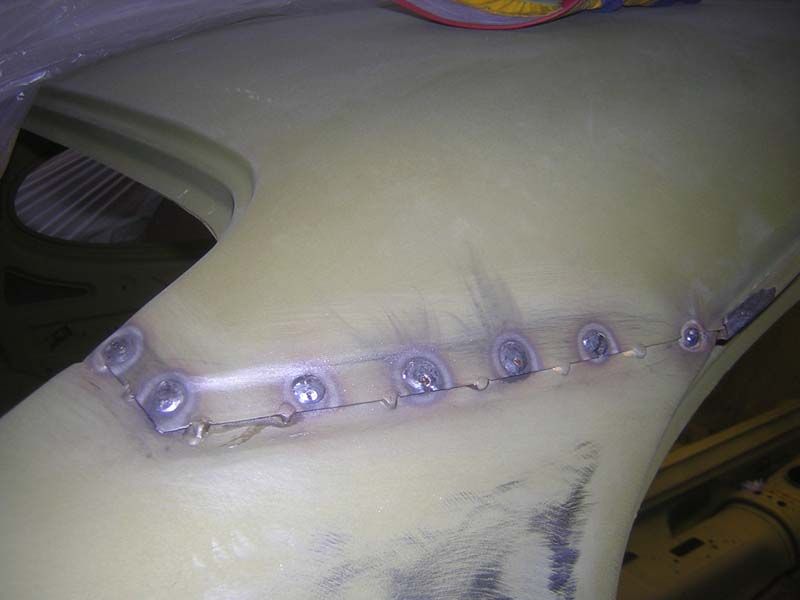

Another view of the outer sill. The bottom rear quarter to sill flange has been remade, butt welded with the thinest skim of filler to make the finish perfect.

It's a similar story on the passenger side, so lower A post and sills, plus small floor repairs..

off with the inner sill..

The same story with the seat mount..

New metal and bottom plate re-spot welded into place..

and a similar repair at the back, forward of the rear spring front mount..

and then this mess in the passenger side foot well. I say mess, but I'm sure most have seen a lot worse!

Sections cut out, including another small section.

and the floor to scuttle seam recreated.

inner sill now in.

and finally outer sill

Follwed by the lower A post repair panel

Anoter area of pin holes on the drivers side A post...

Cut it out and replace

Finally, the roof drilled and plug welded to attach it more securely at these points:

Passenger side strut top. Removing the top strengthener plate revealed an issue underneath, so this needs cutting out..

so this was cut out, all the rust you can see was removed, weld through primer applied and a new plate butt welded into place. Stuart does his repairs like this as they create an invisible repair and leaves no place for rust to hide as can happen if lapped repairs are carried out.

and the repair in place

Here you can see thatt the inner wing stiffener has lifted (the battery tray is on the other side of this) and as ever has created a rust trap. Quite a common capri issue.

so off it comes. Oh dear...

Hmm, this won't be going back on then!

From inside the engine bay with the battery tray removed. There is another repair near the chassis rail. This will be sorted out soon as well.

So the whole section is cut out. You can also see that the reinforcing section below needs attention. the other side of the patch you can see in the previous photo...

A new section is made up and welded into place...

and a new strengthener made up to match the original panel. This will be plug welded into place, with the welds matching the placing of the original welds

strengthener in place

Now that section of the inner wing to chassis section is cut off...

inside the section of chassis and it really is in great condition in there!

The front valance/panel and front box section has been removed. The front panel will be going back on, as it's in great condition, not to mention new ones going for £500 plus!

New half of the cross member in place. It's all primed and sealed, just as Ford would have done. Had they been bothered!

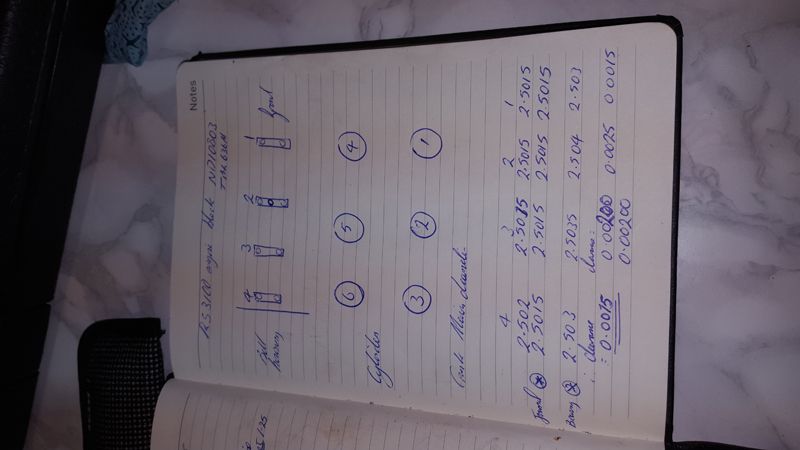

/>/>

This shows the new fromnt half of the cross me,ber in place. It's not welded to the drivers side inner wing just yet, as we are look at replacing the inner wing on that side, as it's quite a bit worse than the passenger side.

Cross member spot welded in place.