Ok, done some chopping:

I haven't chopped the bit in the middle out yet cos I'm afraid the shell will implode. The problem I have now it there there is nothing left of the inner sill to weld floor repair sections to. For this reason the outer will will have to come off to give me access to repair the inner sill.

Not a problem I thought as the outer sill is in bad condition and needs replacing, and on first inspection it seemed that sills were cheap, around £30.

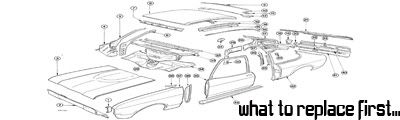

Ok, now look closely at the above pic. It appears the half the sill has been repaired before, but using a sill skin rather than a full sill. It was here I realised the difference between a sill skin and a full sill. The full sill is what I need to do the job properly. It incorporates the door step and is basically the full panel as Ford would have fitted it.

Now if I was restoring a cheap car like a mk1 escort, I could get a sill skin for £15.70, or a full sill for £15.93. No one's gonna do a half assed job for the sake of 23p!

But because I own a mk3 Capri, a sill skin is £12.70, but a full sill panel is £80+VAT and only available from expressed steel panels!

I'm seriously upset about this! I vow I will never try and restore a Capri again, its a job for the wealthy and I just don't have the money to do it properly. If I replaced the panels which need replacing I'd be looking at around £4000!!!

I'm not sure what to do yet. I might hack it together with a skin, or just pay the £100 odd quid to expressed steel. I don't want to do that though cos costs will soon start spiraling our of control.

It just makes me really angry that this is the case. If it was an escort I would be able to afford new valance, slam panel, floor sections, fulls sills, inner wing section, but cos I've got a Capri I can't afford to do the job properly!